Manufacturing Project Mastery: Seamless Industrialisation

from Design to High-Volume Production

Bringing an innovative electronic product from development to mass production can be a complex journey.

At MGX Technologies s. r. o., our industrialisation services bridge this gap, ensuring a seamless, cost-effective, and high-quality transition from prototype to scalable manufacturing.

We act as your expert guide, optimizing every detail to prepare your product for market success at volume.

Our Industrialisation services focus on:

-

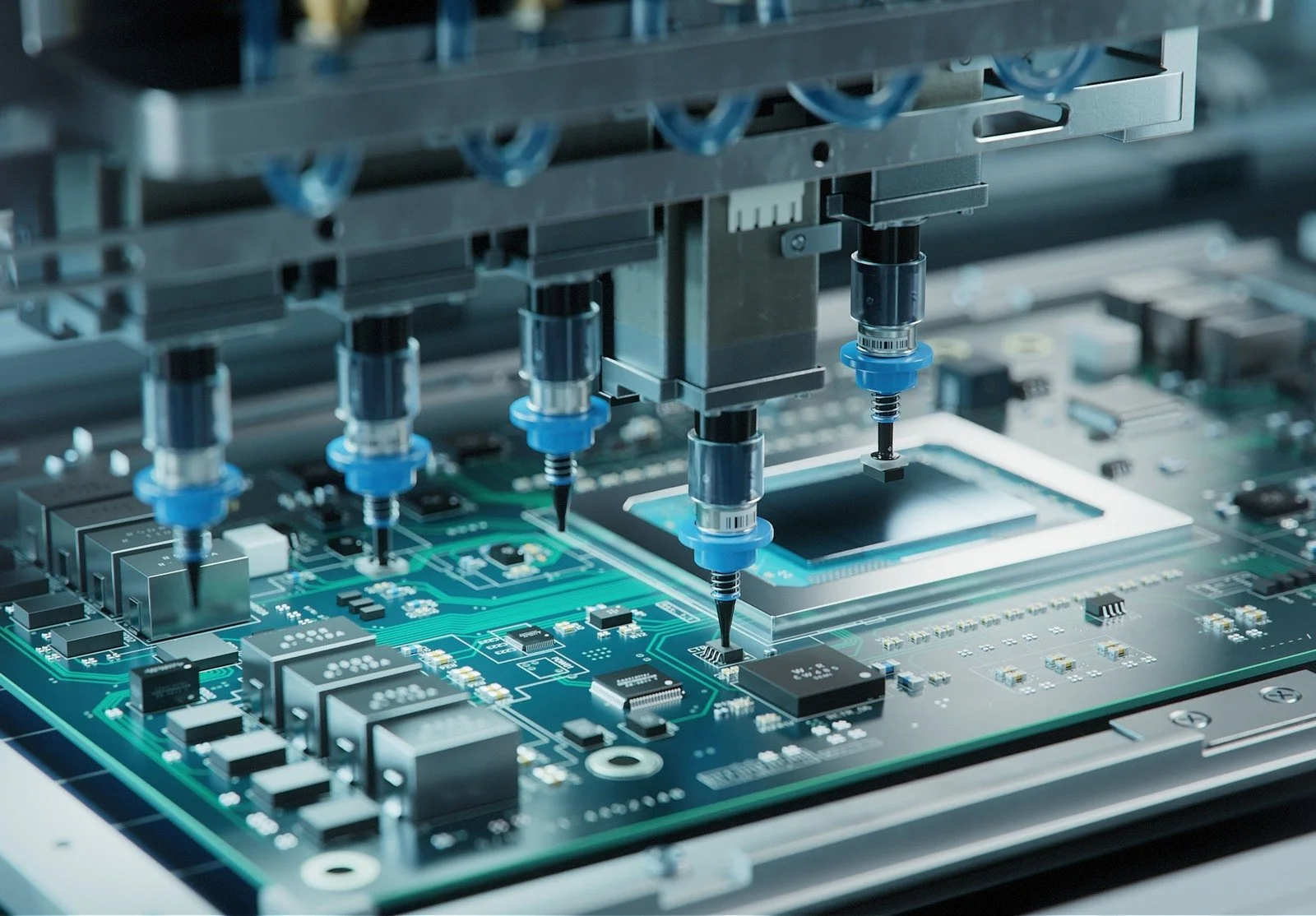

We meticulously review and refine your design to ensure it is inherently manufacturable and assemblable. This proactive approach identifies and resolves potential production bottlenecks, reduces manufacturing costs, minimizes assembly time, and significantly improves overall product yield and quality in volume production.

-

Leveraging our industry network, we assist in identifying reliable component suppliers and establishing robust supply chain strategies. This includes optimizing component selection for availability, cost-effectiveness, and long-term viability, crucial for sustained production.

-

We can help you select the most suitable contract manufacturers (CMs) for your product. We act as your technical liaison, facilitating clear communication, overseeing production ramp-up, and ensuring that manufacturing processes adhere to design specifications and quality standards.

-

We assist in defining and optimizing the manufacturing processes, including assembly instructions, test procedures, and quality control checkpoints. Our goal is to create an efficient and repeatable production flow that ensures consistent product quality and maximizes throughput.

-

Navigating global regulatory landscapes can be challenging. We provide essential support in preparing documentation and advising on requirements for necessary industry and regional certifications (e.g., CE, FCC, RoHS, UL), smoothing your path to market entry.

-

We compile a complete and professional production documentation package, including detailed Bill of Materials (BOMs), assembly drawings, test specifications, and quality control plans. This ensures all critical information is accurately conveyed to your manufacturing partners for seamless production.

Why choose MGX Technologies s. r. o.

for Industrialisation?

Our end-to-end approach ensures a smooth, predictable, and efficient transition to mass production, allowing you to bring your innovative products to market faster, at a lower cost, and with unwavering quality.

The MGX End-to-End Advantage

We don't just prepare for manufacturing; we engineer for cost efficiency. Our DFM/DFA focus and component expertise are aimed at maximizing your profitability by reducing material waste, lowering assembly time, and securing better supply chain pricing.

Cost Optimization and ROI

By managing the entire transition, from final design file preparation to manufacturing partner liaison, we eliminate communication gaps and the risks associated with juggling multiple vendors, ensuring a smooth, coordinated project flow.

Single Point of Accountability

We identify and solve potential production or supply chain issues (like component End-of-Life, or EOL) before they impact your timeline or budget, guaranteeing a more predictable and reliable production ramp-up.

Proactive Risk Mitigation

We take the confusion out of market entry by providing essential support for complex global certifications (CE, FCC, UL, etc.), accelerating your product's compliance and launch timeline.